How do you identify a high tensile fastener?

We use high tensile bolts on parts where require high strength to hold components together firmly. For instance, the linkages of a suspension system, or to hold a brake caliper to the knuckles.

For safety and reliability, it is important to choose the proper grade and the correct installation to ensure you’re safe in your machine. However, the markings on the head face of a bolt can be confusing. So how do we specify the grades between each pattern and make sure the size is correct?

Reading the Head Markings

- First step is to check to see if there are any head markings. The head markings, if present, will indicate if the bolt setscrew is metric or imperial.

Proof Load: The tensioned load that a fastener must support without evidence of permanent deformation.

Tensile Strength: The maximum load that a fastener can support prior to fracture.

Yield Strength: The point at which a tensioned load of a fastener experiences a permanent deformation.

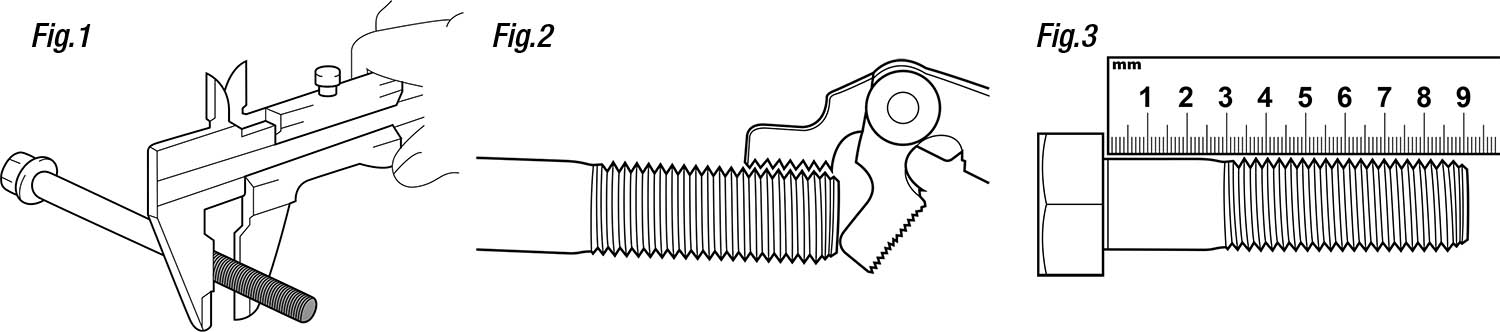

- Second, look at the threaded part of the bolt/setscrew and identify if it is a fine thread or coarse thread. Using a diameter measuring instrument (eg: a vernier) determine the diameter of the threaded part of the bolt/setscrew. (fig. 1)

- Using a pitch gauge determine the pitch of the thread. (fig. 2)

- Finally, using a length measuring instrument (eg: a ruler) measure the length of the fastener from under the head. (fig. 3)

Fighting Corrosion (Rust)

Zinc plating is a valuable tool which is used to combat corrosion of steel. A metal bond is formed between the zinc and the steel, which allows the zinc itself to corrode before the steel. This way the zinc will be sacrificed allowing the steel to remain intact.

Zinc plated fasteners are better suited to a dry environment, if a fastener is required for any sort of wet environment where the effects of corrosion cannot be avoided, a stainless steel fastener should be used.

Yellow Zinc and Clear Zinc, Does the Colour Makes a Difference?

The colour of the fastener is determined by a pigment additive during the electroplating process.

The colour of the fastener is determined by a pigment additive during the electroplating process.

This is why some fasteners appear a “gold(yellow)” colour and some a “silver(clear)” colour. This is purely done for appearance. One colour has no benefit over another.